Story 01

Yamatogawa Route, Hanshin Expressway Route 6

Reduces congestion and smooths logistics.

Routes the highway through long underground tunnels.

Outline

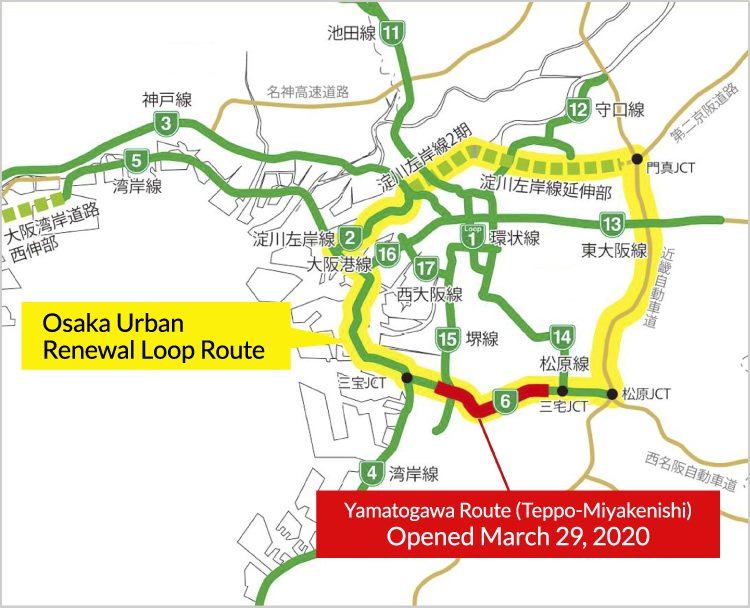

The Yamatogawa Route (Hanshin Expressway Route 6), opened on March 29, 2020, is a 9.7-kilometer highway running east-west between Sakai and Matsubara in Osaka Prefecture. Connecting to the Bayshore Route (Route 4) and Matsubara Route (Route 14), the Yamatogawa Route is expected to help in reducing congestion in city and general roads by improving access to the critical areas of Osaka where logistics are located and to inland areas, such as the manufacturer's row on Nishi-Meihan Expressway.

The route's defining feature is its underground tunnels, through which most of the route passes due to environmental and other considerations. The ground in Osaka is pocked with many obstacles making it difficult to dig tunnels, including subway lines and other large-scale buried structures, along with power lines, gas, and communications infrastructure. In addition, long underground tunnels come with safety requirements not found in other road structures, such as ensuring that everyone can safely evacuate in the event of a large fire. For nearly 20 years, the NEWJEC Road Engineering Group has been grappling with many of these challenges.

Member

-

Takashi Mizuguchi

Transportation and Urban Division

Joined NEWJEC in 2001 as an engineering administrator. Oversees all NEWJEC projects.

Takashi Mizuguchi

Transportation and Urban Division

Joined NEWJEC in 2001 as an engineering administrator. Oversees all NEWJEC projects.

-

Shigeji Yoshinaga

Transportation and Urban Division

Shigeji Yoshinaga

Transportation and Urban Division

Road Engineering Group

No. 2 Road Engineering Team Handles simulations, structural planning, and some design work for tunnel sections. -

Masaharu Inoue

Transportation and Urban Division

Masaharu Inoue

Transportation and Urban Division

Road Engineering Group

No. 2 Road Engineering Team Makes decisions on road alignment and road crossing configuration, and handles fire evacuation methods and guidance marking and signage study and design. -

Junji Kawasaki

Transportation and Urban Division

Junji Kawasaki

Transportation and Urban Division

Road Engineering Group Performs timeline verification, etc. for evacuees and rescuers based on evacuation drills and simulations. -

Shiro Tamaki

Transportation and Urban Division

Shiro Tamaki

Transportation and Urban Division

Road Engineering Group

Bridge Engineering Team Designs bridge sections where the Yamatogawa Route intersects the national highway and where it connects to the Matsubara Route.

Chapter 1

The challenge of long tunnels extending under downtown Osaka

The Yamatogawa Route on the Hanshin Expressway was approved as a city planning project in 2000, and NEWJEC has been involved in development with the clients, including Hanshin Expressway Co., Ltd. and Osaka Prefecture, since the following year. Takashi Mizuguchi, who has worked as a team member in various design and study tasks since the beginning, shares the following.

"The defining feature of the Yamatogawa Route is that most of the 9.7-km route tunnels underground. Until now, most of the Osaka highway system has been elevated. However, with the Yamatogawa Route planned along the Yamato River, underground tunnels were chosen given the emphasis placed on levee reinforcement, landscape preservation, and impact on the surrounding environment. At the time, it was the first urban underground tunnel of its length in Kansai, with only a handful such tunnels even in Tokyo. When we started working on its long tunnels, a first for us, following our initial plans, the issues flooded in: Were there any issues with the overall structure and construction? Were any budgetary revisions needed? How would we secure and manage disaster prevention and keep people safe if a fire broke out in a long underground tunnel? How would it mesh with the surrounding environment? We proceeded through the outline design to preliminary design and detailed design facing these issues, and worked on disaster prevention and other tasks until just before the route opened."

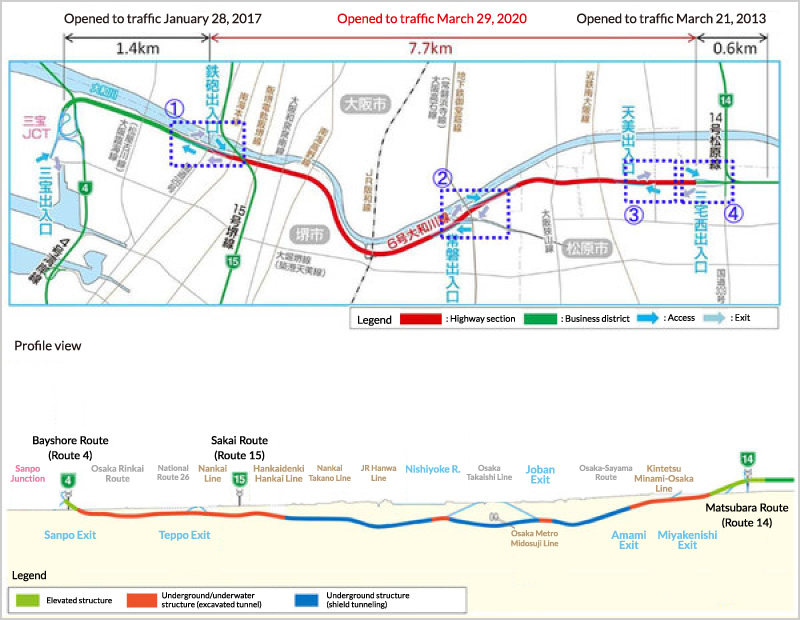

General view

Main NEWJEC work on the Yamatogawa Route

-

- 2001-

- Review of structure, etc. in the master plan

-

- 2005-

- Preliminary and detailed design of the Amami and Tokiwa-Nishi sections

-

- 2008-

- Tunnel disaster prevention evaluations, etc.

-

- 2017-

- Detailed examination of evacuation guidance, etc.

-

- March 29, 2020

- Yamatogawa Route (Hanshin Expressway Route 6) opened

- Received a business award from Hanshin Expressway Company for our 2008-2017 work.

Plane view of Route 6

Chapter 2

The path of the underground tunnels obstructed

Digging a tunnel under the city center involves coordinating various buried utilities: power lines, gas lines, water lines, telecommunications lines. Shigeji Yoshinaga, tunnel expert on the Yamatokawa Route project, reflects:

"At a diameter of 12 meters, the tunneling shield for the Yamatogawa Route tunnels is way larger than utility service tunnels. It was a real challenge thinking of how to build such large tunnels along the Yamato River. For example, the Osaka Metro Midosuji Line passes close to the Joban exit. How should we keep them from interfering with one another? How should we plan the road alignment and depth? What size structural members would we need to ensure strength? Finding the right answers proved very difficult as we went through the few domestic examples and literature grasping for clues in the structural planning. We also worked on the excavation tunnel design for the Amami shielded shaft section where digging would be carried out to a depth of 29 meters, close to the path of the Kintetsu Minami-Osaka Line. The circumstances called for ingenuity; we analyzed for subsidence and other impacts to the ground surface and used an earth retaining wall with members to reduce deflection. In the box culvert sections, we had to appropriately model the complex changing structure for the connection geometry between the traffic lanes and off ramps (sectional width, depth, ramp plane positions, etc.), which went from a double box to a triple box to a quad box. After evaluating with the seismic coefficient method, we designed the structure to ensure seismic resistance.

In all of NEWJEC history, I think it's the first time we've planned and designed a road tunnel of this scale. We did that, with our own hands. It was a great sense of achievement."

There are two types of tunnels on the Yamatogawa Route.

-

Shield Tunnel Tunnels made using a tunneling shield to dig in a cylindrical shape. 40% of the Yamatogawa Route was made with shield tunneling. -

Excavated Tunnel Tunnels formed by excavating the ground and then backfilling soil on top. Suitable for shallow tunnels near the surface.

Chapter 3

Price considerations and repeated improvisation

One of the construction consultant's roles is to examine the economics of plans to see it through to fruition. While keeping safety and security priority number one, we look to reduce costs. Bridge expert Shiro Tamaki also made repeated improvisations from a budgetary standpoint in his bridge design.

"I was working on the overpass connecting to the Matsubara Route (Hanshin Expressway Route 14) at the far east end of the Yamatogawa Route. Normally, bridges run about 10 meters wide, but with the toll gates and all this section wound up being 39 meters wide-about the same as the bridge length. It was almost square. A bridge structure is divided into the superstructure for the highway itself and the substructure upon which the bridge is built. On the superstructure, given the volume of concrete we could pour in a day, we compared several ways of breaking it up, looking for the best plan in structural, budgetary, and workability terms. We wound up slicing the bridge in three in the axial direction, which is a particularly cost-efficient method.

Also, given the width, going with a wall-like structure for the substructure would have bumped up the volume and costs for concrete, as well as greatly increase the impact of contraction upon drying. Instead, we went with a gated rigid frame structure with PC steel member inserts. Aesthetics are also important, so we used a semi-circular frame to round the corners and soften the angular image of a concrete bridge. I tweaked things wherever possible, with the budget always in mind. That's what satisfies me."

Chapter 4

Unprecedented disaster prevention measure: An evacuation slide

"In my almost 20 years working on the Yamatogawa Route, the most difficult part was tunnel disaster prevention. There were very few domestic examples to draw from, and we did not have any experts among us. Under the circumstances, we needed to establish a disaster operation plan." -Takashi Mizuguchi

How does smoke spread in large-scale blazes in a long underground tunnel? How do you keep people safe in such situations? What equipment is needed and what procedures should be followed to evacuate? Junji Kawasaki simulated various considerations and created evacuation guidance scenarios.

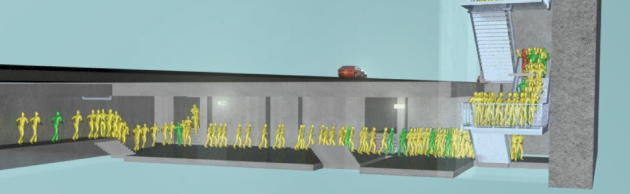

"The Yamatogawa Route has the first tunnel in Kansai to employ an evacuation slide. Originally, we were thinking of evacuating people to the tunnel running parallel for opposing traffic. With more safety considerations made, however, we changed over to having people evacuate by dropping under the road within the tunneling shield hole and using a shaft connecting to the surface. The change was made in 2017. There were only three years to the tunnel opening for service, and we didn't have a set design criteria or any drawings to work with. With that we held repeated discussions between the NEWJEC members and clients, poring over relevant literature and domestic and international cases. Our issue was how to verify our expected evacuation timeline: with the tunnel still under construction, no verification testing was possible. What I proposed was to use the distinct element crowd behavior simulator, a joint research project with Dr. Hitoshi Gotoh of Kyoto University, who I know from my graduate school days, to analyze the movement of people during a fire. In this simulator, evacuees and rescuers can freely act in a three-dimensional VR space. We checked for crowding points and calculated the time it took for them to evacuate underground from the fire and reach the surface via the complex underground space. From this, we were able to create a highly accurate timeline and verify our evacuation guidance.

After the tunnel was completed, we verified the results through actual field testing. For the field testing, we had stakeholders alongside kids and elderly from the general public evacuate as if an actual fire occurred. It was a big relief when the evacuation went safely and smoothly in line with the expected timeline. Every day was a slog, but doing something unprecedented like this with no manual made it that much more satisfying to complete. I remember telling the client, 'This is the first real engineering work I've done in years!' It was an engineer's dream come true."

-

Evacuation slide Evacuees open a door at the emergency exit and use a slide to escape to safety under the road. From here, they walk up an evacuation route to the surface. -

Simulation study example

Chapter 5

On site right up until the day before opening

At the same time evacuation guidance was being decided, directions and signs within the tunnel had to be implemented. With the first evacuation slide, exactly what sort of directions and signs would best get evacuees to quickly understand how to use the slide system for probably their first time? Tasked with planning and design for these directions and signs was none other than Masaharu Inoue.

"In a fire, you have to evacuate all kinds of people: people unfamiliar with the evacuation method, inbound tourists, those with limited vision. Nevertheless, we set up design codes that provide visuals and color schemes that illustrate in an instant that this is an emergency exit, and here you take the slide down. Wall signs alone for showing the path and such can get obstructed and be missed, so we took care to display directions on the floor as well.

There was plenty to think about other than signs as well. For instance, guardrails: where best to position them so that the disabled and those with wheelchairs could smoothly slide down and transition to getting back up. Also, what kind of cushioning to lay so that evacuees didn't hurt themselves when sliding down. And where to strategically position benches along the evacuation route for the elderly and other weakened individuals to rest. We examined each and every one of these questions with all the clients. In many cases, you had to actually see it in action; that was important. Like if we put a sign to view head on along the route then the viewer might stop in their tracks, so we'd decide to offset the positioning a bit. Things like that.

There were also a lot of last-minute tweaks and adjustments, so I was running around site with the client literally up until the day before the tunnel opened to traffic. I worked on all this with a few younger second- and third-year members. For them, it was highly motivating to actually see what we had designed implemented in the field."

Chapter 6

Best if not used

The project safely delivered to the clients, the Yamatogawa Route opened to traffic on March 29, 2020. While highway traffic volume has been temporarily down, partially due to the COVID-19 pandemic, traffic has steadily grown since the Yamatogawa Route has opened.

"Now over a year since the opening, it's relieving that there haven't been any major accidents to date. We worked hard on all these tunnel disaster prevention measures, but the best outcome would be if no one ever has reason to use any of the disaster prevention equipment or manuals." -Takashi Mizuguchi

Throughout the Yamatogawa Route project, NEWJEC mobilized all its technologies and knowledge to take advantage of the natural features of the Yamato River and to consider the aesthetics and living environment. The Yamatogawa Route will make everyone's lives in Osaka more convenient and richer by making transportation more convenient and logistics more efficient, thereby invigorating the economy. This project embodies the NEWJEC ideal as represented in our catchphrase: Technology in Harmony with Nature and People.