Story 05

Hirara Port

Port improvement for a remote island to provide supplies uninterrupted while keeping the ocean beautiful

Outline

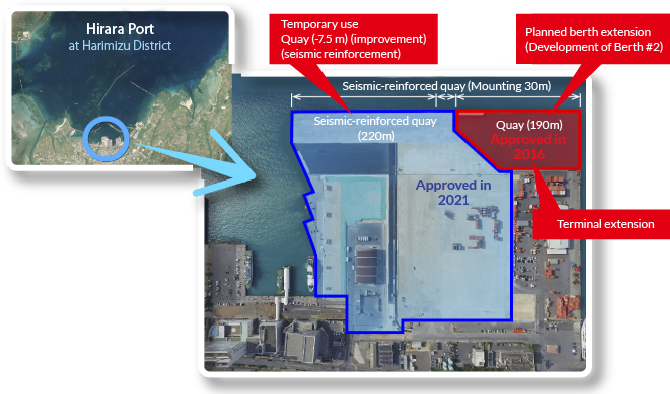

The island of Miyakojima is located about 300 km southwest of the main island of Okinawa. Surrounded by coral reefs and cobalt blue seas, this island relies on regular RORO cargo ships from Okinawa Island to transport everyday and industrial supplies. Serving as Miyakojima's gateway and only port, Hirara Port is important but deteriorating. Not equipped to cope with ships of ever-increasing size, the port is growing difficult for ships to enter and is inefficient at loading and unloading cargo. Also, Hirara is the only port in Okinawa Prefecture without a seismic-reinforced quay, leaving it prone to an interruption in transportation of goods in the event of a larger earthquake. Given this, a terminal improvement project for Hirara Port was started in 2011. NEWJEC was entrusted with a series of project tasks, including the feasibility study and ground motion study, basic design and implementation design of the quay, and application for a land reclamation license for public waters.

Member

-

Sosuke Nishimura

Corporate Planning Operations /

Sosuke Nishimura

Corporate Planning Operations /

Port and Coastal Engineering Group Involved in the project as administrative engineer since 2011. With his extensive experience, Nishimura heads up the entire project. -

Aya Makino

Transportation and Urban Division,

Aya Makino

Transportation and Urban Division,

Port and Coastal Engineering Group,

Port Planning Team Involved in the project since 2011. Makino handled future demand estimates based on interviews with port users and increasing tourists, and examining the impact of investments. -

Toshiyuki Hirai

Transportation and Urban Division,

Toshiyuki Hirai

Transportation and Urban Division,

Port and Coastal Engineering Group Since joining NEWJEC in 1996, Hirai is an earthquake specialist engaged in research and technical development on earthquakes and seismic reinforcement. For this project, Hirai worked on preparing the design ground motion and the relevant field investigation. -

Shinichi Yoshikawa

Transportation and Urban Division,

Shinichi Yoshikawa

Transportation and Urban Division,

Port and Coastal Engineering Group As the administrative engineer for the design portion of the project, Yoshikawa led as many as eight members in the design process. Yoshikawa used his innate creative prowess in designing a seismic-reinforced quay. -

Maiko Takeuchi

Transportation and Urban Division,

Maiko Takeuchi

Transportation and Urban Division,

Port and Coastal Engineering Group,

Coastal Environment Team Takeuchi prepared the necessary applications for the land reclamation work and documents for environmental impact assessments of air and water quality, noise, and vibration. Working with the design team, she helped to shorten the schedule.

Chapter 1

Fulfilling wishes to improve Hirara Port

Hirara Port acts as the gateway for goods transport on Miyakojima. On Miyakojima, the islanders had all long wished for a port renewal. The port had two major issues: It was unequipped to handle larger cargo ships, and it lacked a seismic-reinforced quay. These issues reduced the logistical efficiency in normal operations and carried the risk of port service coming to a halt in the event of a large earthquake. Miyakojima City had constantly pleaded with the national government for port improvements to overcome these issues, but the project never materialized. This was the state of affairs in 2011, the year of the Great East Japan Earthquake. Having just partnered with the Okinawa General Bureau, which has jurisdiction over Hirara Port, NEWJEC considered improvement plans for the project. Our challenge to fulfill the island's wishes to restore Hirara Port had begun!

Major NEWJEC efforts

-

- 2011

- Feasibility study (Berth #1)

-

- 2012

- Prepared design ground motion

-

- 2012

- Basic design and implementation design of quay (Berth #1)

-

- 2016

- Feasibility study (Berth #2)

-

- 2016

- asic design and implementation design of quay (Berth #2)

-

- 2016

- Application for land reclamation of public waters (Berth #2)

-

- 2017

- Provisional start of service for the intermodal transportation terminal at Harimizu District in Hirara Port

-

- 2021

- Project reassessment (GPS-enabled investigation of actual cargo handling in the terminal to confirm achievement of initially assumed effects)

Chapter 2

Gather information from a unique perspective and prove the need

Sosuke Nishimura, the project's administrative engineer, knows how tough it is to get project approval. "Port improvements are public works projects costing tens of billions in yen. To get such a project approved requires acknowledgment from a third-party organization such as the Ports and Harbors Subcommittee of the MLIT Council for Transport Policy that the project is worth the investment. Also, as every port across the country is requesting improvements from the government for its own issues, it is important to illustrate the need for improvement from a unique perspective in order for the project to get approved." Since joining NEWJEC in 1994, Nishimura has worked on the planning and design of numerous port facilities. He frequently visited Miyakojima in search of unique information.

He noted containers crowding the wharf, and trailers protruding out onto nearby roads. He witnessed forklifts and tractor units using their sheer skill to weave left and right to find a path through the tight spaces. Cargo handling at Hirara Port was even more inefficient and dangerous than he had imagined. Viewing the scene made evident the issues and the necessity for improvement. The question was how much of that could be communicated through the pages of documentation alone.

Nishimura met with wharf workers and measured by stopwatch the time it took them to perform cargo operations. From his years of experience, Nishimura also turned his attention to other neighboring ports in the area.

"I was curious: how long did it take to do the same cargo tasks at other ports? In my head, I both wanted a base of comparison and thought that maybe Hirara Port's inefficient cargo handling was somehow impacting logistics in Okinawa."

-

A crowded wharf -

Freight overflowing from the wharf site -

Congestion in cargo handling

Chapter 3

The key to approval lies off island. Follow the RORO ships

Taking the lead for Nishimura in the investigation on nearby ports was Aya Makino, a member of the Nishimura team then in her third year at NEWJEC. Packing a stopwatch and camera in her bag, Makino traveled the sea route along with a RORO ship from Naha Port to Hirara Port and then to Ishigaki Port. She recorded the state of each port and the time taken for cargo operations.

"Thinking it best to remove as many variables as possible to make an accurate comparison, I suggested that we take all measurements from a single ship," says Makino. "It was physically exhausting, but I think it clearly illustrated the current state at Hirara Port."

Just as Nishimura had predicted, the cargo handling delays at Hirara Port also had an impact at Ishigaki Port. Continues Makino:

"It's not uncommon in this region for a delivery originally scheduled for an evening arrival to show up the next morning, or for goods not to show up for a while if bad weather strikes, causing continued delivery cancellations. Our conclusion was that improvements to Hirara Port were necessary for stable goods transportation not only for Miyakojima, but throughout Okinawa Prefecture."

During her investigation of Ishigaki Port, Makino actually witnessed a regular ship missing its delivery.

"Even missing regular deliveries for just one day can leave convenience stores and supermarkets running out of stock. And if the quay were to get destroyed in a disaster... It felt imperative to get the project accepted, no matter what it took."

Makino aimed her camera at an empty shelf to snap another picture to add to the materials. Based on Makino's investigations and through repeated discussions with the Okinawa General Bureau, the team prepared an improvement plan. Once done, they continued to refine the plan through repeated feedback from the Council of Transport Policy Ports and Harbors Subcommittee. Finally, after about a year, the long-desired project was approved.

Chapter 4

The ground motion geek squad assembles to fix a data shortage

Once the project was approved, work on preparing a design ground motion began for designing the seismic-reinforced quay. Ground motions are ground vibrations as caused by earthquakes. Also engaged in work on dams, power generation facilities, and other critical infrastructure, NEWJEC has many engineers experienced at forecasting ground motion. Hirai is one such engineer. For many years, Hirai's work included measuring vibrations in dams and analyzing seismic response in slopes at power plants.

"We ran ground motion forecasts for Hirara Port in 2012," starts Hirai. "With the Great East Japan Earthquake occurring off the Pacific Coast the previous year, associated research unearthed many new facts on the mechanisms behind ground motion, including which parts of a fault will release strong energy. For Hirara Port, we decided to quickly take these new facts into account in preparing the design ground motion."

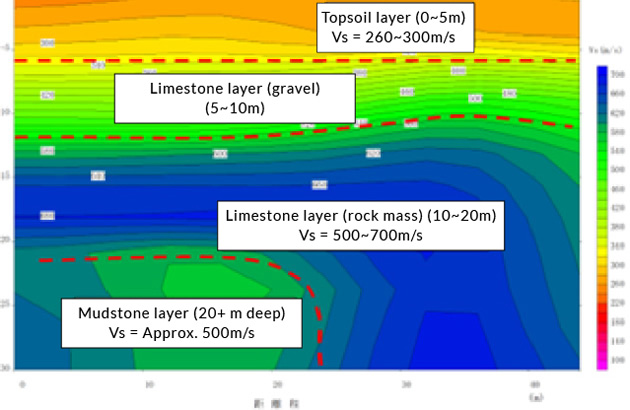

However, during simulations, it was found that the data from the provided boring survey was insufficient. With that, Hirai, along with two NEWJEC engineers affectionately known within the company as "the ground motion geek squad," headed out immediately to conduct a field investigation. The squad estimated the underground structure from ground surface surveys, taken with two methods: The surface wave method and the microtremor method. The surface wave method involves planting geophone sensors at regular intervals, and then striking the ground with a hammer to measure the vibrations. Meanwhile, the microtremor method is to measure naturally occurring vibrations from the wind, waves, and other sources. Hirai reflects fondly on the experience with a chuckle.

"It was fun! Normally you'd expect everyone to be in a panic if there's not enough data to go off, but we were excited. 'Yes, we get to go investigate!' It's a typical scene at NEWJEC, where engineers who love their work assemble. I doubt many construction consultants would go investigate underground structure themselves."

-

Hammer vibrations and data recording (Measurement line B) -

Figure 3.1-16 Shear-wave velocity structure (Measurement line B)

Chapter 5

Building a seismic-reinforced quay with locally sourced, fragile stone

Based on the Hirai team's design ground motion, design for the seismic-reinforced quay started in 2012. In the quay design, Shinichi Yoshikawa was particular about a certain aspect.

"It's common in seismic reinforcement to improve the soil by mixing in cement and such to fortify the foundation ground. But doing that would impact the environment by causing turbidity in the surrounding sea water. This design avoids the need for major soil improvements to the extent possible so as not to affect the clear ocean waters of Miyakojima."

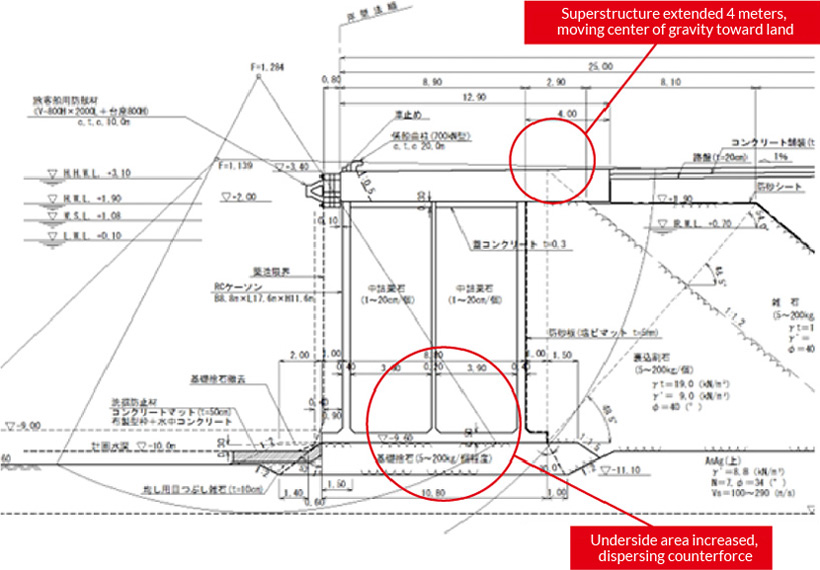

Also, with Miyakojima being a remote island, ordering more materials and construction equipment would balloon transportation costs. Therefore, it was also necessary to choose methods that could be completed with a local construction company using only materials on the island. With these restrictions, Yoshikawa chose the caisson method. In this method, a riprap foundation is built on the sea floor. Then, huge concrete boxes called caissons are placed on the foundation and packed with gravel or other materials to stabilize them. The structure is designed to withstand external forces through the self-weight and frictional force of the quay.

"The caisson method isn't some special method and so can be completed with local resources."

But there was one problem: the white stone material, called 'shiroishi' stone, that was used for the foundation. Shiroishi stone is readily extracted on Miyakojima from Ryukyu limestone. While readily available, the stone was brittle and unsuited to the caisson method, which requires a certain weight. With that, Yoshikawa worked to increase the caisson width in order to disperse the counterforce on the underside of the caissons and limit the pressure applied to the shiroishi stone. In addition, in sections, the superstructure installed on top of the caisson extends 4 meters in toward the land. This design shifts the center of gravity in toward the land so that in the case of any strong shaking, no excessive pressure will be applied to the shiroishi stones on the sea floor. For his work on this design, Yoshikawa was awarded the Award for Businesspersons and Engineers by the client: the Hirara Port Office of the Okinawa General Bureau. An interview with Yoshikawa was also featured in a local Okinawan newspaper.

"I felt the heft of Miyakojima resident expectations for the Hirara Port improvements. I'm just happy to have made even a small contribution to the development of the region."

Chapter 6

Starting work 2 months early by completing design and land reclamation application simultaneously

With land being reclaimed to expand the terminal, this project required an application for land reclamation on public waters. Preparing this application was another task undertaken by NEWJEC. At that time, many Japanese ports were competing to attract large cruise ships, and there was a desire in Hirara Port as well to start using part of the berths on the quay by 2020 to join in the competition. Thus, while such applications are normally prepared after the design is completed, in this case the applications were prepared concurrent with the design process. Maiko Takeuchi reflects on her work at the time.

"The application must include any number of items. In addition to the design outline, it's required to explain why land reclamation is needed and what impact the reclamation work or presence of the landfill site will have on the environment in terms of water and air quality, noise, vibration, and so on. However, we had trouble finding the information needed for simulations, such as the amount of landfill soil and construction method. Also, anytime the work machinery or vehicle quantities or processes were altered, we had to rework the various items associated with each change. It was tough."

As Takeuchi tells it, they were able to complete the process concurrent with the design because NEWJEC was able to handle all the planning and design.

"For one, if you were missing a certain figure, you could simply ask the engineers to produce it as soon as possible. Also, many company members were working on Hirara Port, so if there was something I didn't know, I could just ask someone and get an answer. Members working together so closely is precisely what made it possible to prepare the applications and design simultaneously."

The application for reclamation on public waters was submitted just as the design was completed. Teamwork had shortened the schedule by almost two months.

Chapter 7

An emotional opening ceremony, looking to a full open in 2024

In 2017, 220 of the 440 meters planned for berth use were provisionally opened. The port already allows 10,000-ton class RORO ships and 50,000-ton cruise ships to dock. Nishimura was present at the provisional opening ceremony.

"This is the first time in my career that I've been invited to an opening ceremony. It was a great honor. I had a flood of emotions at the ceremony when that first RORO ship entered port and docked safely. That's not the end of the job for us though. The real sense of accomplishment will come when all the work is done and the port can provide the islanders an uninterrupted flow of supplies."

The port will be fully open for service in 2024. NEWJEC looks forward to continued involvement in the development of Hirara Port as well as other ports in Okinawa Prefecture.

-

Provisional opening ceremony -

Provisional opening ceremony