Story 04

Aigawa Dam Project

A beautiful urban masonry dam

that protects residents from floods and improves the environment

Outline

Aigawa Dam appears as a beautiful stone masonry wall between two mountains. Located about 20 minutes' drive from Ibaraki City in Osaka Prefecture, the dam is novel among Japanese urban dams for being made primarily of stone and rock rather than concrete. It is scheduled to start service in 2023. A variety of peripheral facilities are also scheduled to open in 2024, including a 410-meter suspension bridge as a symbol of the Hokusetsu area, making it the longest in Japan, and the Skywalk, which will be visible from downtown Osaka on clear days.

Conceptually, Aigawa Dam was envisioned more than half a century ago back in 1967. That July, torrential rains in Hokusetsu caused extensive flooding, taking 61 lives. In addition to protect lower basin residents from flooding and protecting the environment, the facilities will connect Ibaraki to the mountains for tourism and recreation, creating new value for the city as a whole. The large-scale Aigawa Dam Project has been a company-wide effort at NEWJEC now for many years.

Member

-

Toshiyuki Akamatsu

Dam Engineering Group,

Toshiyuki Akamatsu

Dam Engineering Group,

River Division Project Leader. Since 2002, Akamatsu has worked in dam design, construction planning, estimations, and external activites related to Aigawa Dam. -

Kenji Shimoyama

Earthquake Resistance Team,

Kenji Shimoyama

Earthquake Resistance Team,

Dam Engineering Group,

River Division Works on changes to the water utilization plan in accordance with changes to the river source plan and checking seismic performance in the construction phase. -

Yuji Yoshida

Design Team,

Yuji Yoshida

Design Team,

Dam Engineering Group,

River Division Involved in the final design and construction planning for the dam body. In the construction phase, Yoshida is in charge of foundation treatment analysis of the dam as constructed. -

Takahiro Yamashita

Design Team,

Takahiro Yamashita

Design Team,

Dam Engineering Group,

River Division Yamashita headed up order estimations and construction equipment design for the dam body, and handles design for modifications during the construction phase. -

Toshiyuki Negishi

Steel Structure Team,

Toshiyuki Negishi

Steel Structure Team,

Dam Engineering Group,

River Division Negishi heads detailed design and mechanical equipment design for the water diversion and outlet facilities, and lock gates for initial filling.

Chapter 1

Providing safety in the lower basin even against 100-year torrential rains

The dam measures 76.5 meters in height and 337.5 meters across the dam crest. The magnificent form of the masonry dam was nearly complete by December 2021, more than 50 years after the dam was first envisioned. Project Leader Toshiyuki Akamatsu, who has worked on the Aigawa Dam Project for 20 years since 2002, shares his thoughts.

"The Aigawa River watershed in northern Osaka Prefecture has long been plagued by flooding. Osaka Prefecture started the Aigawa Dam Project back in July 1967, when torrential rains in Hokusetsu caused a massive flood killing 61 and flooding 25,000 houses. Osaka wanted flood controls to keep the town safe even in a 100-year flood. NEWJEC has been involved in Aigawa Dam construction operations since the beginning. This dam project involves more than just a dam and would not be possible without combining various technologies, including river, geospheric, telecommunications, and architectural technologies. This large-scale project has been a company-wide effort, taking advantage of the strengths of our being a general construction consultant."

In 1976, surveying for dam construction got underway. In 1993, road diversion work started. In 2005, however, that steady progress met with significant changes. "Osaka Prefecture made some changes to the water resource plan. The Aigawa Dam is built both for flood control (regulating water volumes during flood events) and water utilization (service water, etc.). Originally, the dam was planned to produce 70,000 cubic meters a day for water utilization. The prefecture cut this down to 10,000 cubic meters."

Kenji Shimoyama, who was working on change plans to the dam scale at that time, expounds. "We simulated how much the dam capacity should be trimmed with this change in the water resource plan. During the process, we walked with members of the River Engineering Group involved in the Aigawa Dam Project from the dam site down to Kanzaki River. Another important factor with rivers is maintaining enough water volume to keep it attractive from a landscape perspective. We surveyed the residents as well. It's more than just numerical data; seeing it with your own eyes is an important aspect of planning."

As a result of the water resource plan revisions, the dam capacity was reduced. The required dam height was changed from 82 meters down to 76.5 meters.

Aigawa Dam Timeline

| 1976 | Surveying for dam construction commences |

|---|---|

| 1988 | Construction starts for the dam and facilities |

| August 1993 | Road diversion work commences |

| August 2005 | Osaka Prefecture changes the water resource plan (water utilization cut from 70,000 m3/day to 10,000 m3/day = dam height cut from 82 m to 76.5 m) |

| August 2009 | Due to the revised water demand forecasts, the prefecture withdraws from water supply operations at Aigawa Dam |

| September 2010 | All sections of diversion road opened, and national government requests Dam Construction Project verification |

| June 2012 | Dam Construction Project verification completed. Project continues. |

| December 2012 | River diversion work ordered |

| March 2014 | Dam body construction ordered |

| August-October 2022 | Initial filling commences |

| 2023 | Scheduled start of dam service |

NEWJEC has handled planning, surveys, and various testing for the dam, as well as dam site and dam modeling, defining the dam axis, project verification, dam body design and construction planning (incl. machinery, telecommunications facilities, and buildings), river diversion work, and estimates for dam body work. Since work commenced, NEWJEC has attended and responded to more than 100 bedrock adjudication committee meetings in total. We have also designed modifications according to the site conditions and conducted grouting analyses for water cutoff measures. Moving forward, we plan to measure and analyze the dam body behavior during the initial filling.

Chapter 2

A service spillway tunnel, nearly unprecedented in Japan

With the dam capacity and height determined, the project transitioned to the precise final design and construction planning for the dam body. Yuji Yoshida, who worked together with Akamatsu on the design, recalled the design being quite a challenge.

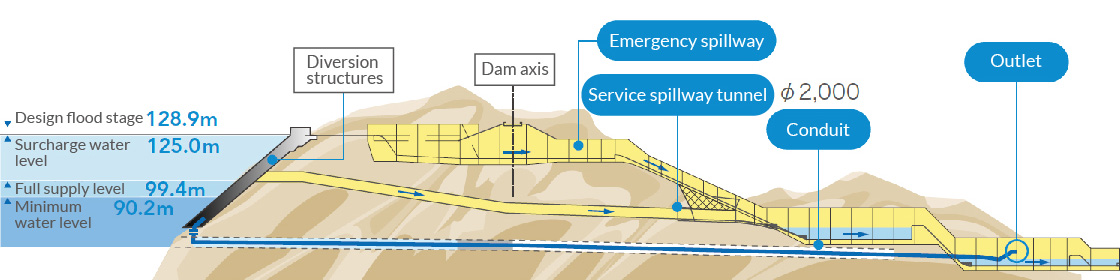

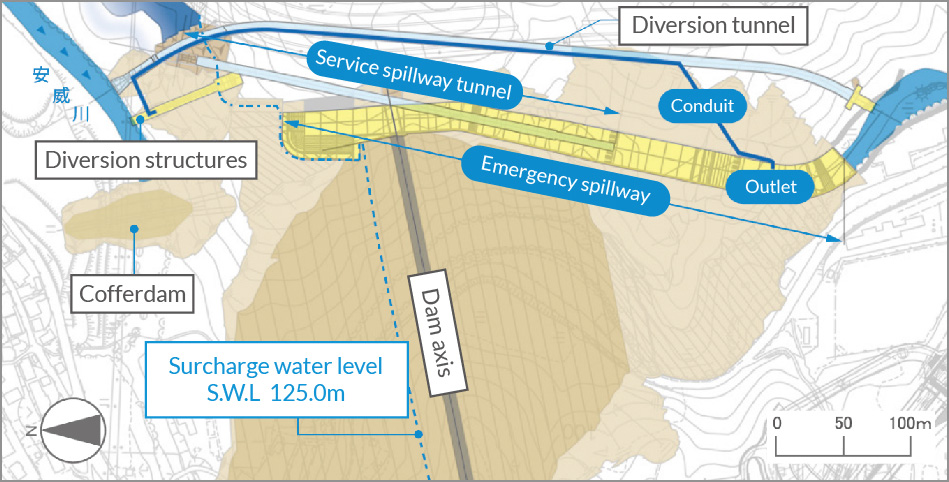

"With dams, there are two routes for runoff to flow in times of flooding, called flood spillways. The first is the service spillway tunnel*1, and the other is called the emergency spillway*2. Aigawa Dam employs a natural flood control system, in which water flows naturally over these two flood spillways according to the reservoir elevation with no input from human operators.

Now, on a regular dam, the service spillway tunnel is built by forming a waterway on the ground surface. However, attempting this at Aigawa Dam would position the spillway quite low on the dam. The massive amount of digging in the mountains involved would result in equally massive costs. The only way to avoid this is to dig holes to create a service spillway tunnel.

However, service spillway tunnel are structurally complex with almost no precedents in Japan. But could it be done? When I asked Akamatsu, he replied with a chuckle, 'Well, nothing's impossible. We might as well try.'"

The team ended up building a fairly large 1/40-scale hydraulic model and then started testing it. While verifying the water flow and necessary structures one by one, all the obstacles toward achieving the service spillway tunnel were gradually cleared.

- *1) Service spillway tunnel

The service spillway tunnel is designed to safely release water downstream from the reservoir in the event of rainfall or flooding within the scope of the dam flood control plan. - *2) Emergency spillway

This facility releases water downstream from the reservoir to keep reservoir water levels from exceeding the dam height, even for rainfall or flooding in excess of the dam flood control plan.

-

Cross-section of flood spillway conduit -

Top-down view of flood spillway conduit -

Emergency spillway -

Hydraulic model test of service spillway tunnel

Chapter 3

Dam flushing turns crisis into opportunity

In August 2009, four years after changing the water resource plan, Osaka Prefecture threw Akamatsu another piece of shocking news: Due to further revised water demand forecasts, they were pulling out of water supply operations altogether. This rendered the 10,000 cubic meters per day of planned water utilization capacity from four years ago unnecessary.

With that, the required dam height was reduced by another two meters to 74.6 meters. Reflecting, Akamatsu laments:

"Here we had proceeded with testing and design based on a 76.5-meter dam height, and we were going to have to lower it by another 2 meters. We'd have to start all over; all our work and expenses to that point would go completely to waste. That was the one thing I wanted to avoid." How could the capacity once required for water use be utilized effectively without changing the dam height? This was Akamatsu's chance to show his skill.

"Dams work to stop major flooding, but they also reduce the likelihood of smaller, everyday discharges. With no turbulence in the river, there are concerns that dams can change the downstream river environment. To combat this, water is artificially released from the dam to create a better ecosystem for fish and other living creatures. This action, called a dam flush, is a flexible operation utilized with dams in recent years. Given the emphasis placed on the environment with this urban dam, I approached Osaka Prefecture with the idea of repurposing the service water for dam flushes to add environmental capacity. While no existing dams in Japan are equipped with facilities capable of regular flushing, I thought future dams might need such capability in light of environmental protections."

Following verification of the structural feasibility of installing the flushing equipment and further environmental impact assessments, the prefecture approved Akamatsu's proposal to proceed without changing the dam height. The river ecosystem would benefit, and their work and expenses to that point would not go completely to waste. Thus, Aigawa Dam became the first dam in Japan to be nationally recognized as having an artificial discharge (flushing) capacity for preserving the river ecosystem. Crisis gave way to opportunity. This turned out to be a great turning point in the project.

Chapter 4

Calculating estimates from more than 1,000 drawings

In August 2010, just over a year after Akamatsu's brilliant idea to implement dam flushing, the national government demanded an examination of the need for dam projects. Aigawa Dam was one of the projects targeted in the examination. Willed somewhat by Akamatsu's desire to continue the project after coming so far, but also on the strength of its cost-effectiveness, the project made the cut and was approved to continue.

At that point, design documents (drawings, bills of quantity, specifications, etc.) would be necessary to solicit tenders for the construction. Drafting such drawings is part of the project. Says Akamatsu with a laugh, "The quantity estimates might have been hardest part of this project. The construction was going to cost about 25 billion yen, and there were more than 1,000 drawings for the tendering package. What kind of heavy machinery were to be used, how many dump trucks would be needed to haul the stone, how wastewater was to be treated? It took the Group's entire design staff a full year to complete the daunting task of calculating all the money needed for construction."

Takahiro Yamashita, who would subsequently work on design in the construction phase, was in his second year with the company when he was asked to help with the estimates. "It's unthinkable to me now, but at that time I never knew when I'd have enough time to go home and take a bath again."

Chapter 5

Unexpected strata impede construction

In March 2014, the order for dam construction was finally placed. Says Akamatsu of the time, "No matter how much you survey beforehand, there are bound to be surprises that don't match the survey when construction starts. In this case, we had geologists analyze the boring study results and designed the dam based on those results. When the actual excavations started, however, we stumbled upon some weak strata that had gone undiscovered in the survey phase. The ground was more weathered than expected with occasional deformations in the slope and other irregularities. In some areas, the cutting lines had to be altered. Altering the cutting line takes time, extending deadlines and expanding costs. How to reach the best solution? We consulted with the client (Osaka Prefecture) and the general contractor repeatedly as we worked through it."

Yamashita, who helped Akamatsu in designing the structural modifications, shares his perspective. "In the construction phase, the layout is already decided. Unlike a new design, modification designs add the wrinkle of figuring out how to solve the problems under constraints such as the work schedule, workplace safety, and shape changes during construction. It was quite the ordeal working together with the geologists to figure out improvement measures based on site conditions."

In addition to the civil works, the project also includes a machinery team. On designing the water diversion and outlet facilities and the lock gates for the initial filling, Negishi speaks on the challenges faced with so many firsts for him.

"It took numerous discussions with Osaka Prefecture to decide the target discharge volume for the dam flushes, which had become a prime feature of the dam. It was tough: Changing the discharge volume even slightly would change everything from the size of the required gate to all the motors of the associated hoisting device and other machinery. Dam gates absolutely cannot break, so it is always tense work."

Chapter 6

Checking our work with the initial filling

Seven and a half years later in December 2021, the final embankments for the dam crest atop the piled rocks were completed. The dam wasn't finished just yet, however. The summer of 2022 saw the start of initial filling, in which the dam is actually filled with water. In the initial filling, the dam is filled to the maximum water level (also called the "surcharge water level") according to the flood control plan and then lowered to normal water level (full supply level-minimum water level). This process confirms the safety of the embankments and the slopes around the reservoir. More than 50 years in the making, after verification through initial filling, NEWJEC's Aigawa Dam Project will finally come to an end when the dam enters service in 2023.

Yoshida, currently analyzing the construction results, had this to say. "We refer to initial filling as 'checking our work.' If no problems arise in the initial filling, it gives me pride as an engineer. At the least, I hope for a passing grade without having to redo anything."

Project Leader Akamatsu, who has worked on the dam for more than 20 years, also gave his thoughts. "The dam reaches the maximum water level in the initial filling. You get to see the most exciting moment for a dam builder: watching water flowing through the emergency spillway. I look forward to it. Primarily, the emergency spillway at Aigawa Dam will only see use in the event of a 100-year torrential rain. I hope the dam never experiences those levels outside of the initial filling."

In the Aigawa Dam Project, NEWJEC has demonstrated its Kuroyon Spirit, putting forth a company-wide effort to overcome numerous barriers and facing difficult situations without giving up. Aigawa Dam will reduce flooding damage in the watershed, protect resident lives, land and property, and is sure to become a beloved tourist spot and symbol of the Hokusetsu area.